Manufacturing

Our component warehouse is efficiently managed with an advanced warehouse management system (WMS), which is designed to support an overall management of components to ensure quick processing of client’s orders. The bar code system uses a database configured to support warehouse operations.

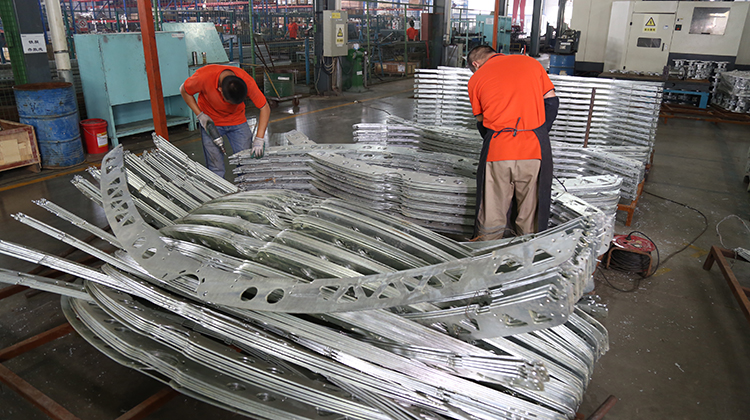

The Vicot Frame production workshop focuses on the production of solar collector frames. The workshop is equipped with two CNC lathes, one CNC machining center, two large-power laser cutting machines and several welding machines which are essential for the solar collector frame’s production. All structural elements production is related to the bulk production for molds and fixtures, which enjoys a high machining capacity and high machining efficiency, aptly supporting a daily production for 350m2.

The assembly workshop is responsible for diverse processes, including installation, helium leak detection, combustion system pre-installation, evacuation, online-testing for gas absorption heat pump and packaging. The workshop is able to support a monthly production of 1,000 pieces.

Component warehouse is outfitted with a warehouse management system (WMS), which is designed to support an overall management for components and to ensure the fast production of our orders. The system use a database configured to support warehouse operation – bar code.

Component warehouse

Component warehouse  Take stock for components

Take stock for components

Frame production workshop is mainly designed for the production of solar thermal collector frame. The workshop is equipped with two CNC lathes, one CNC machining center, two large-power laser cutting machine and some welding machines which are essential for solar collector frame’s production. All the structural elements’ production is related to the bulk production for molds and fixtures, which enjoys a high machining capacity and high machining efficiency, well supporting a daily production for 350m2.

Machining workshop

Machining workshop  Hole drilling

Hole drilling

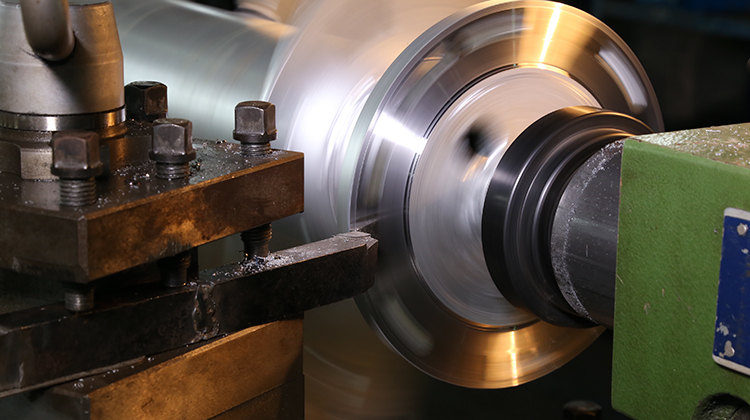

Vicot is outfitted with a horizontal lathe, which is lengthened for longer working length – 4 meters. With processing of the lengthened horizontal lathe, our components will enjoy a high accuracy, which helps to achieve the installment requirements towards solar collector.

Horizontal lathe

Horizontal lathe  Close-up for horizontal lathe

Close-up for horizontal lathe

Argon arc welding will be carried out for our workpieces, which allows a high weld strength, small solder joint and fast welding. Thus, a high welding accuracy and a long serving life could be ensured.

Argon arc welding

Argon arc welding Close-up for argon arc welding

Close-up for argon arc welding

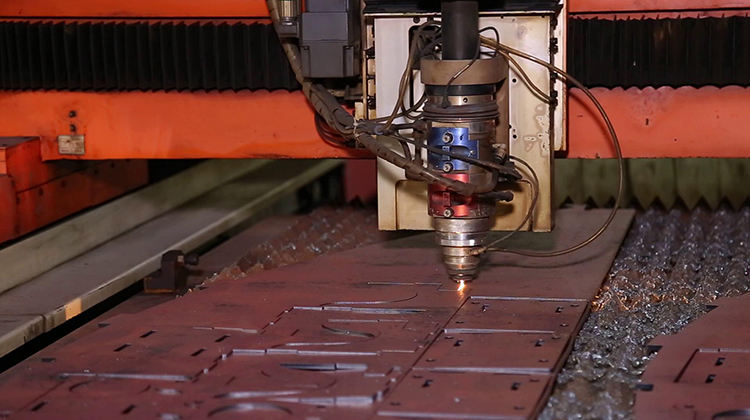

Laser cutting machine

Laser cutting machine Laser cutting machine control unit

Laser cutting machine control unit

Vicot’s laser cutting machine features relatively high cutting accuracy with a tolerance of 0,1mm, as well as a super-high machining capacity, which allows the cutting for objects with a thickness of 16mm.

Close-up for laser cutting machine

Close-up for laser cutting machine

Assembling line is responsible for diverse processes, mainly including electric generator’s assembly, pipeline welding, helium leak detection, heat pump installation, wire-to-board connection, online detection of heat pump and final assembly.

The start of assembling line

The start of assembling line  Medium section of assembling line

Medium section of assembling line

Online-detection of heat pump

Test preparation work in assembling line

Test preparation work in assembling line Online-detection of heat pump

Online-detection of heat pump

Final assembly

Final assembly

Vicot Group

Factory Location: Hongdu Road, Dezhou Economic Development Zone, Dezhou City, Shandong Province

Add. (Imp. & Exp. Office): A1, 4th Floor, Building 2, Shuntai Plaza, Jinan Innovation Zone, Jinan City, Shandong

Tel:

+86-531-88255580

+86-531-88255563

Fax: +86-531-88255591

Email: export@vicot.com.cn

Website: www.vicot.com.cn